A spherical shape of particles is welcome in the sphere of AM systems. Sphericity is a big edge for good flowability of metallic powders, regardless of whether irregular particles can easily improve green toughness with no achieving uniform density10.

Polyurethane's have really powerful weatherability qualities. They supply great anti-corrosion efficiency and therefore are proof against humidity and a range of substances and oils.

Within the changing circumstance of pharmacy follow in India, for successful exercise of Medical center Pharmacy, the students are necessary to master many capabilities like drug distribution, drug dispensing, producing of parenteral preparations, drug information, individual counselling, and therapeutic drug monitoring for improved affected person treatment

Several drug carriers are below improvement like liposomes, nanoparticles, microparticles to attenuate drug degradation and improve bioavailability. NDDS can offer controlled release of prescription drugs more than extended durations as a result of formulations like sustained launch and focused supply to particular websites in your body.

Definition of drying Significance of drying Distinction between drying and evaporation Drying is defined as removal with the liquid from a cloth by software of warmth & is accomplished by transfer of a liquid from the surface area into an unsaturated vapor stage . Drying is the final removing of drinking water from materials (usually by warmth) Drying is usually the final stage in a very manufacture course of action Non-thermal drying one- As Squeezing wetted sponge two- Adsorption by desiccant (desiccation) three- Extraction.

Hybrid Hybrid powders are blends of epoxy and polyester resins. As a result, they provide outstanding mechanical Homes and Superb chemical and corrosion resistance.

is supposed being enlightening in mother click here nature, nonetheless it shouldn’t take the put of advice and/or supervision from a professional medical professional.

Sintering is the process of binding a material together with heat without liquefying it. It is frequently executed at atmospheric pressure and less than meticulously managed environment composition. To acquire Unique Attributes or Improved precision, secondary processing like coining or warmth therapy often follows.[five]

This analyze aiming at probiotic pill formulations delivers an method of obtain a higher survival charge from the microorganisms by the correct selection of excipients and approach parameters.

The next worth of the linear slope signifies a move resistance. For Fe powder the slope of the line corresponds to an exceedingly lower price near to zero, which is an indication of free of charge-flowing check here powder.

The document discusses a variety of approaches utilized for size separation of particles in pharmaceutical procedures. It defines different powder sizes according to mesh aperture sizes. Some widespread size separation strategies explained are sieving, sieve shaker, cyclone separator, air separator, filter luggage, and elutriation tank.

Granulations Granules are particles ranging in size from about 4 to 10 mesh. Granules typically are created by 1st Mixing the powders alongside one another then moistening the mixture to sort a pasty mass. The mass is handed through a sieve and then dried in air or within an oven.

1. Desiccation is the process of wholly taking away mechanically mixed drinking water from substances utilizing a desiccator made up of a desiccant like calcium chloride. It can help lessen the bulk, excess weight, and price of transporting and storing medication by eliminating water. two. Sublimation is the method wherever a good converts on to vapor without passing through a liquid phase, and vice versa through condensation.

The faucet density of the powder signifies its random dense packing. As an example, a sufficient faucet density will help to be certain sufficient packing of powder layers and superior eco-friendly density9. The alternative may be considerable porosity and subsequent higher shrinkage throughout sintering. This can lead to the condition of accomplishing the specified density of the final product10.

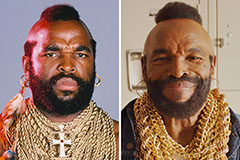

Mr. T Then & Now!

Mr. T Then & Now! Tia Carrere Then & Now!

Tia Carrere Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now!